CV Joint Internal Bore Grinding Machine -- Outer Race Internal Bore Grinding

In automotive driveline systems, constant velocity (CV) joints are responsible for transmitting torque smoothly under varying angles and operating conditions. Within the CV joint assembly, the outer race features a highly complex internal structure and operates under extremely severe load conditions. The machining accuracy of the outer race directly determines transmission smoothness, noise performance, and overall service life of the CV joint.

Importance of the Outer Race in CV Joints

The outer race is the primary load bearing component of a CV joint. Structurally, the outer race consists of a working section and a connecting section. The working section of the outer race includes the inner spherical surface and multiple longitudinal ball tracks evenly distributed along the spherical surface. The connecting section of the outer race includes stepped shaft surfaces, external splines, and external threads.

During operation, the outer race must withstand continuous cyclic torque transmitted from the engine, while simultaneously accommodating angular variations caused by steering and suspension movement. Because the outer race is exposed to complex alternating loads and impact forces, it typically undergoes special heat treatment processes such as carburizing and quenching. These processes ensure high surface hardness of the outer race while maintaining sufficient core toughness.

As a result, after heat treatment, the outer race requires high-precision grinding to guarantee dimensional accuracy and geometric stability of the critical internal bore and reference surfaces.

Internal Structure and Working Principle of the Outer Race

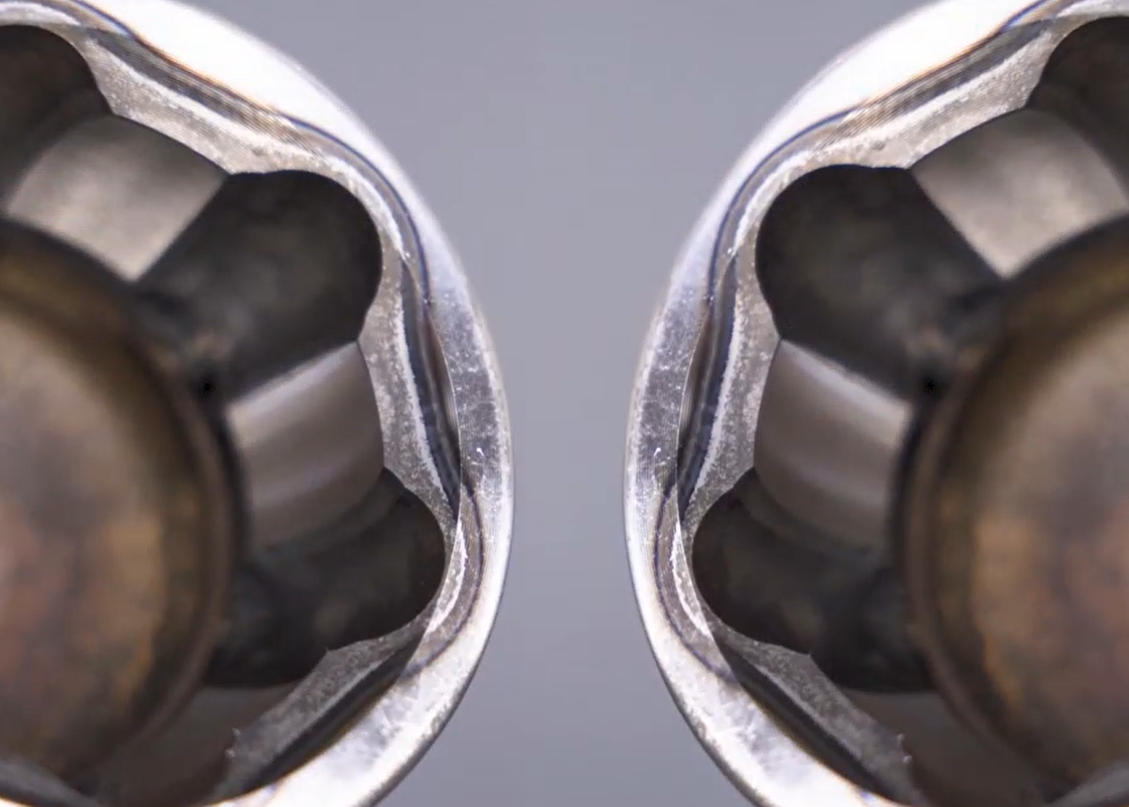

From a structural perspective, the outer race contains a precisely machined inner spherical surface and six uniformly distributed ball tracks. These ball tracks inside the outer race form a specific geometric relationship with the inner spherical surface, creating a dual-offset structure between the ball track centerlines and the sphere center.

This unique internal geometry of the outer race allows the CV joint to maintain constant angular velocity between the input shaft and output shaft even under changing working angles.

During operation, steel balls roll between the ball tracks and the inner spherical surface of the outer race, transferring torque through controlled rolling motion. Therefore, the machining quality of the outer race internal bore, spherical surface, and related reference features plays a decisive role in ball movement stability. Any deviation in roundness, coaxiality, or surface roughness of the outer race internal bore can result in increased vibration, higher noise levels, and reduced service life of the CV joint.

Necessity of Internal Bore Grinding for the Outer Race

After heat treatment, the outer race material exhibits high hardness, making conventional turning processes insufficient to meet modern precision and consistency requirements. For this reason, internal bore grinding has become the preferred finishing method for the outer race.

By using a dedicated CV joint internal bore grinding machine, manufacturers can achieve stable micron-level roundness, excellent coaxiality, and superior surface finish for the outer race internal bore. The grinding process ensures that each outer race meets strict automotive quality standards.

Importantly, outer race internal bore grinding is not merely a dimensional finishing operation. The internal bore of the outer race serves as the primary datum for subsequent ball track grinding and final assembly. This makes the outer race internal bore grinding machine a key piece of equipment within the entire CV joint production line.

Key Features of the Outer Race Internal Bore Grinding Machine

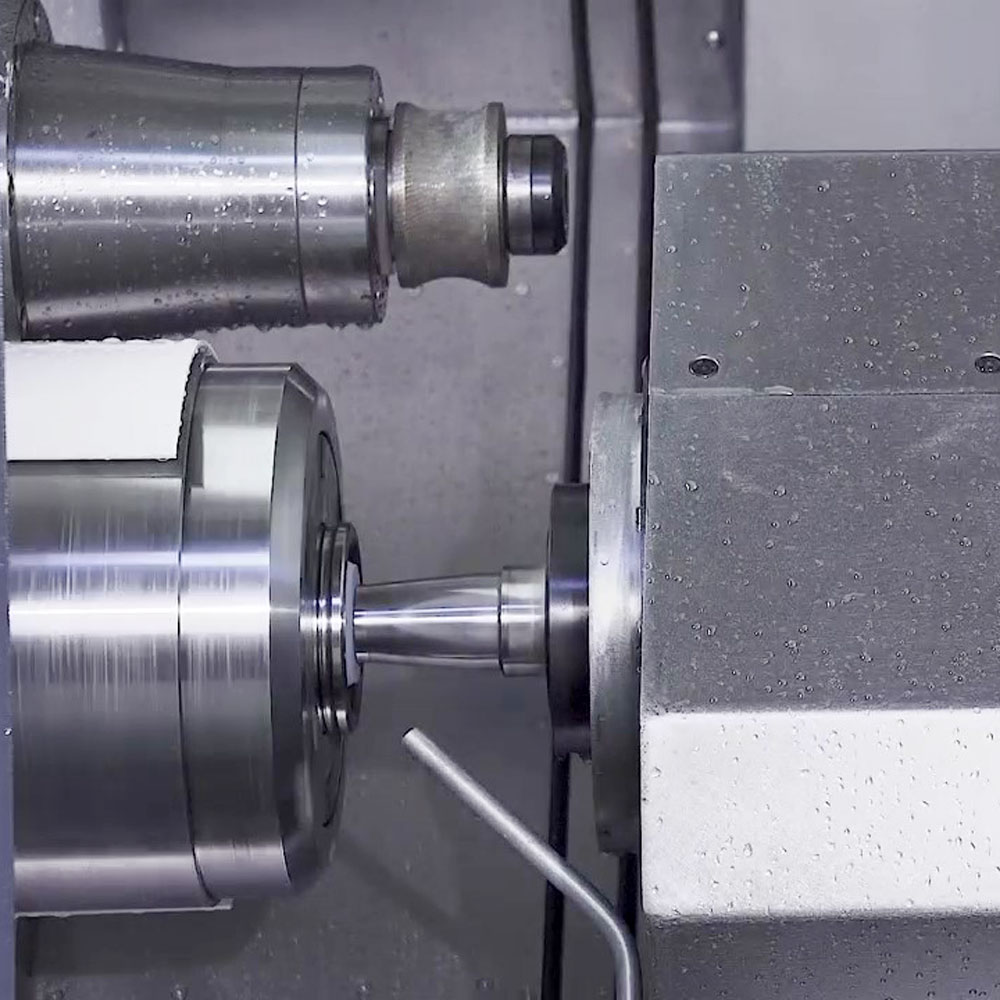

In the third phase of customer equipment delivery, a dedicated internal bore grinding machine was supplied specifically for outer race and cage window machining. The machine design fully reflects the machining characteristics of the outer race:

45 degree slant-bed high rigidity machine structure

Designed for outer race grinding conditions, offering optimized force distribution, excellent vibration resistance, and long-term accuracy stability.

High speed linear guideway system

Ensures smooth and precise grinding feed, supporting high cycle production of outer race components.

Dedicated outer race fixtures

Fixtures developed according to outer race geometry provide reliable clamping and high repeat positioning accuracy, ensuring consistent internal bore quality.

High rigidity motorized spindle

Ideal for continuous grinding of hardened outer race components, featuring excellent vibration damping and long service life.

Servo driven diamond roller dresser

Supports free form surface dressing to meet different outer race internal bore profiles.

Automation ready configuration

Compatible with gantry or articulated robots, enabling automatic loading and unloading of outer race components and seamless integration into automated production lines.

.jpg)

Technical Specifications and Application Range

The outer race internal bore grinding machine is engineered to cover mainstream CV joint production requirements:

Maximum clamping diameter: 115 mm

Maximum workpiece length: 260 mm

Outer race internal bore diameter range: 45-100 mm

Grinding wheel diameter range: 30-50 mm

Maximum outer race shank diameter: 40 mm

These specifications allow flexible adaptation to multiple outer race models while maintaining high grinding accuracy and production efficiency.

Application Cases and Customer Value

In practical production environments, this CV joint internal bore grinding machine has been widely used in mass production lines for outer race components. The machine enables stable, continuous machining of various outer race types with consistent quality.

By optimizing the outer race internal bore grinding process, customers significantly improved roundness and coaxiality consistency of each outer race, reduced assembly rejection rates, and enhanced overall CV joint performance. When combined with automation systems, manual intervention in outer race machining is greatly reduced, resulting in higher productivity and process reliability.

Conclusion

As the core load bearing component of the CV joint, the machining quality of the outer race directly influences driveline performance, noise behavior, and durability. Through the use of dedicated outer race internal bore grinding machines and proven grinding technology, manufacturers can meet stringent precision requirements while building stable and scalable automated production lines. With increasing demand for quieter and more reliable automotive drivelines, outer race internal bore grinding will continue to play a critical role in CV joint manufacturing.