CNC Automation Solutions for Automotive Parts Manufacturing

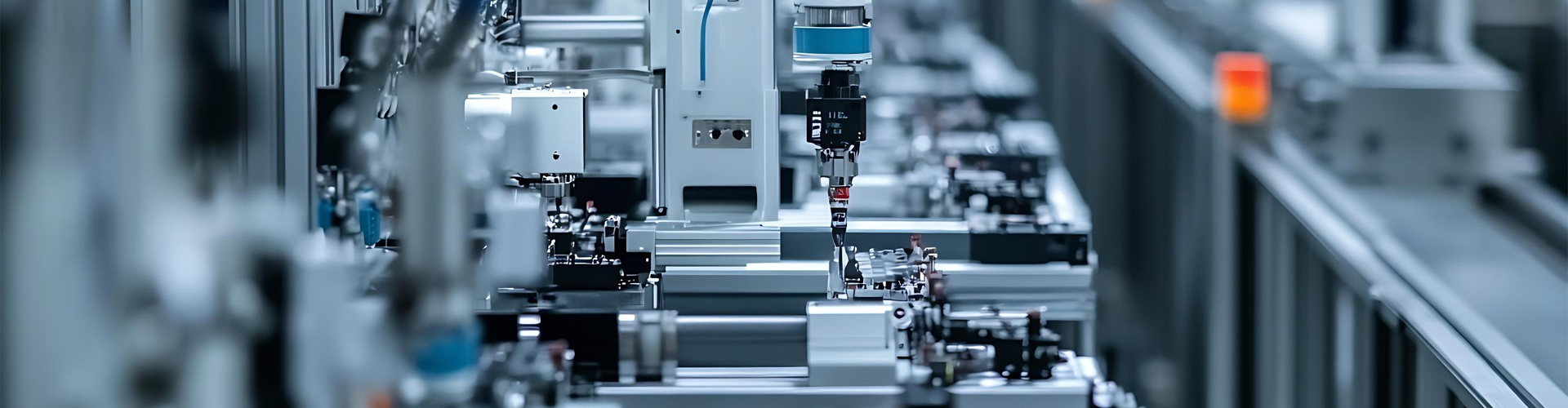

CNC automation has become a critical requirement in modern automotive parts manufacturing. As demand increases for higher precision, stable quality, and large scale production, traditional manual operation can no longer meet efficiency and consistency requirements. CNC automation enables manufacturers to build automated production lines that integrate machining, loading, inspection, and material handling into a continuous process.

In automotive parts manufacturing, especially for gears, shafts, and CV joint components, CNC automation significantly improves machining accuracy and production stability. By combining CNC machines with feeding manipulators and automated production line systems, manufacturers can achieve efficient grinding, chamfering, and rolling processes while reducing labor dependency. CNC automation is no longer an upgrade option--it is a necessary step toward sustainable and competitive manufacturing.

Typical CNC Automation Configuration

A complete CNC automation solution is built from several functional automation modules. These modules work together to form a stable automated production line suitable for automotive parts manufacturing.

Robotic Loading & Unloading

Robotic loading and unloading is a core element of CNC automation. By using a CNC machine loading manipulator, raw parts are automatically positioned into the machine, and finished parts are unloaded without manual intervention. This ensures stable cycle time and consistent positioning accuracy during CNC automation processes such as grinding and chamfering.

Gantry Automation System

A gantry automation system is widely used in CNC automation for medium- and high volume production. It allows one manipulator to serve multiple CNC machines, forming a flexible automated production line. Gantry based CNC automation is especially suitable for gear machining and shaft processing in automotive parts production.

Automatic Gauging and Inspection

To ensure quality consistency, CNC automation systems often integrate automatic gauging and inspection units. Inline inspection enables real-time quality control during automated production line operation, reducing scrap rates and ensuring that every automotive part meets specification requirements.

Conveyor & Pallet System

Conveyor and pallet systems connect different CNC automation stations into a unified automated production line. They allow smooth part transfer between machining, inspection, and unloading stations, supporting continuous CNC automation without bottlenecks.

Unmanned Night Shift Operation

One of the most important advantages of CNC automation is unmanned night shift operation. With stable automation solutions and reliable CNC machines, manufacturers can run automated production lines continuously, maximizing equipment utilization and reducing overall production costs.

Single CNC Machine + Automation = Scalable CNC Automation Solution

CNC automation does not require a full automated production line from the beginning. Many manufacturers start CNC automation by upgrading a single CNC machine with an automatic feeding system or CNC machine loading manipulator.

This approach allows:

Lower initial investment

Faster automation implementation

Gradual expansion into a full automated production line

A single CNC machine combined with a feeding manipulator can already achieve basic CNC automation for grinding, chamfering, or rolling operations. As production demand increases, additional automation modules can be added, forming a scalable CNC automation solution tailored to automotive parts manufacturing.

Typical Application: CV Joint and Gear Components

CNC automation is widely applied in the production of CV joint components and gear parts. In CV joint manufacturing, components such as outer race , cage, inner race, and tripod housing require high dimensional accuracy and surface consistency.

Through CNC automation, CV joint components can be processed in an automated production line that includes:

Automatic loading of raw parts;

CNC machining and grinding;

Chamfering and rolling operations;

Automatic unloading and inspection;

For gear machining, CNC automation ensures stable gear quality during continuous rolling or grinding processes. Feeding manipulators maintain precise positioning, while automated inspection guarantees consistent quality across large production batches.

These CNC automation applications are especially suitable for automotive parts suppliers targeting OEM level quality requirements.

CNC Automation Based on Customer Drawings

All CNC automation solutions for automotive parts manufacturing must be based on customer provided drawings and technical specifications. Drawing based manufacturing ensures that CNC automation systems are properly configured to meet exact part geometry, tolerance, and application requirements.

By using customer drawings, CNC automation systems can be optimized for:

Accurate fixture design;

Stable automated loading;

Consistent machining quality;

Seamless integration into automated production lines;

This approach ensures that CNC automation delivers reliable and repeatable results for OEM automotive parts production.

How to Choose a Reliable CNC Automation Supplier

Choosing the right CNC automation supplier is essential for successful automation implementation. A professional CNC automation supplier should be able to:

Provide customized CNC automation solutions

Integrate automation with existing CNC machines

Support automotive parts manufacturing applications

Deliver long term technical support and system optimization

A reliable CNC automation partner focuses not only on equipment supply but also on complete automated production line performance.

Conclusion

CNC automation is transforming automotive parts manufacturing by improving efficiency, quality consistency, and production flexibility. Through modular CNC automation solutions--ranging from single-machine automation to full automated production lines--manufacturers can achieve stable grinding, broaching, and rolling processes with reduced labor dependency.

By integrating feeding manipulators, inspection systems, and conveyor modules, CNC automation enables scalable, reliable, and future-proof manufacturing solutions for automotive parts and CV joint components.

Learn more about feeding manipulator solutions →