Part of our CNC automation solutions→

Feeding Manipulator for CNC Machine Automation

The Role of Feeding Manipulator in CNC Automation

In modern manufacturing, CNC automation is no longer limited to machine tools themselves. The efficiency and stability of an automated production line largely depend on how workpieces are loaded and unloaded. A feeding manipulator plays a critical role in CNC automation by connecting manual material handling with fully automated machining processes.

For automotive parts manufacturing, such as gears, shafts, and CV joint components, manual loading often becomes the main bottleneck. By integrating a feeding manipulator into CNC automation systems, manufacturers can achieve stable cycle times, consistent positioning accuracy, and reliable unmanned operation. As a key module of CNC automation, feeding manipulators enable CNC machines to operate continuously and efficiently within an automated production line.

What Is a Feeding Manipulator in CNC Automation?

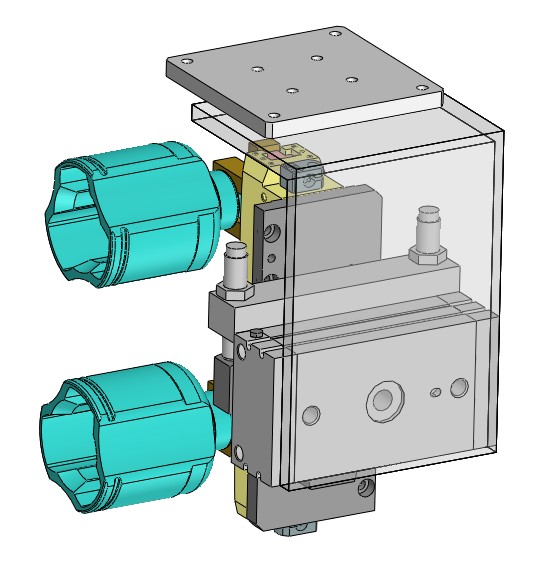

A feeding manipulator is an automatic handling device designed to load raw parts into CNC machines and unload finished parts after machining. In CNC automation systems, the feeding manipulator replaces manual operation and ensures repeatable and precise part positioning.

As a CNC machine loading manipulator, it can be applied to:

CNC scraping and milling machine;

Through an automatic feeding system, the feeding manipulator becomes the foundation of a scalable CNC automation solution.

Why Feeding Manipulator Is Essential for CNC Automation

Stable Cycle Time in Automated Production Line

In CNC automation, inconsistent manual loading leads to unstable production rhythm. A feeding manipulator ensures each loading and unloading cycle follows a fixed timing, allowing CNC machines to operate at their designed capacity. This stability is essential for building a reliable automated production line.

Improved Machining Accuracy

In processes such as grinding, chamfering, and rolling, accurate positioning directly affects machining quality. A CNC machine loading manipulator provides repeatable positioning accuracy, reducing human error and improving overall CNC automation performance.

Reduced Labor Dependency

One of the main objectives of CNC automation is to reduce reliance on skilled operators. Feeding manipulators enable long-term, continuous operation with minimal human intervention, supporting unmanned or night shift production.

Typical CNC Automation Configuration with Feeding Manipulator

A feeding manipulator is usually integrated with other automation modules to form a complete CNC automation solution.

Feeding Manipulator + Single CNC Machine

This is the most common entry-level CNC automation solution. A single CNC machine combined with a feeding manipulator and simple automatic feeding system allows manufacturers to achieve basic CNC automation with limited investment. It is ideal for gear machining, chamfering, or rolling operations.

Feeding Manipulator+Multiple CNC Machines

In batch production, a feeding manipulator can be combined with a gantry system to serve multiple CNC machines. This configuration forms a compact automated production line and significantly improves equipment utilization.

Feeding Manipulator+Automatic Inspection

For automotive parts, quality consistency is critical. Feeding manipulators can work with automatic gauging and inspection systems, enabling closed-loop CNC automation where machining and inspection are seamlessly connected.

Feeding Manipulator Applications in Automotive Parts Manufacturing

Gear Machining Automation

In gear production, feeding manipulators are widely used for automatic loading and unloading of gear blanks. Combined with CNC gear hobbing or grinding machines, CNC automation ensures consistent gear quality during continuous production.

CV Joint Components Automation

CNC automation is especially important for CV joint components such as outer race (bell housing), cage, star sleeve, and tripod housing. Feeding manipulators enable automatic handling of these components between machining stations, ensuring stable grinding, chamfering, and rolling processes.

Shaft and Spline Processing

For shaft-type automotive parts, feeding manipulators maintain precise axial positioning during CNC automation. This improves machining consistency and supports high-volume automated production lines.

Feeding Manipulator Based on Customer Drawings

All feeding manipulator solutions are developed based on customer-provided drawings and technical requirements. Drawing-based manufacturing ensures that the feeding manipulator, fixtures, and CNC automation configuration are fully matched to the specific workpiece geometry and machining process.

By using customer drawings, CNC automation systems can be optimized for:

Accurate gripper and fixture design;

Stable automated loading and unloading;

Seamless integration with CNC machines;

Reliable operation within automated production lines;

This approach ensures that each feeding manipulator solution meets exact application requirements.

Advantages of Choosing a Professional Feeding Manipulator Supplier

A reliable feeding manipulator supplier should offer more than standard equipment. Professional CNC automation suppliers provide complete solutions, including:

Customized feeding manipulator design;

Integration with existing CNC machines;

Support for gear and automotive parts machining;

Flexible automation configurations;

Long-term technical support and optimization;

By working with an experienced CNC automation partner, manufacturers can achieve efficient and scalable automation solutions.

Feeding Manipulator as a Scalable CNC Automation Solution

A feeding manipulator is not only a loading device--it is the foundation of CNC automation. Starting with a single CNC machine and feeding manipulator, manufacturers can gradually expand toward a fully automated production line.

This scalable CNC automation strategy allows:

Step-by-step automation investment;

Reduced implementation risk;

Flexible production capacity expansion;

Conclusion

Feeding manipulators are a core component of CNC automation and automated production lines. By integrating feeding manipulators with CNC machines, manufacturers can achieve stable loading, improved machining accuracy, and reduced labor dependency.

Whether applied to gear machining, CV joint components, or shaft processing, feeding manipulators enable practical, scalable, and reliable CNC automation solutions for automotive parts manufacturing.