.jpg)

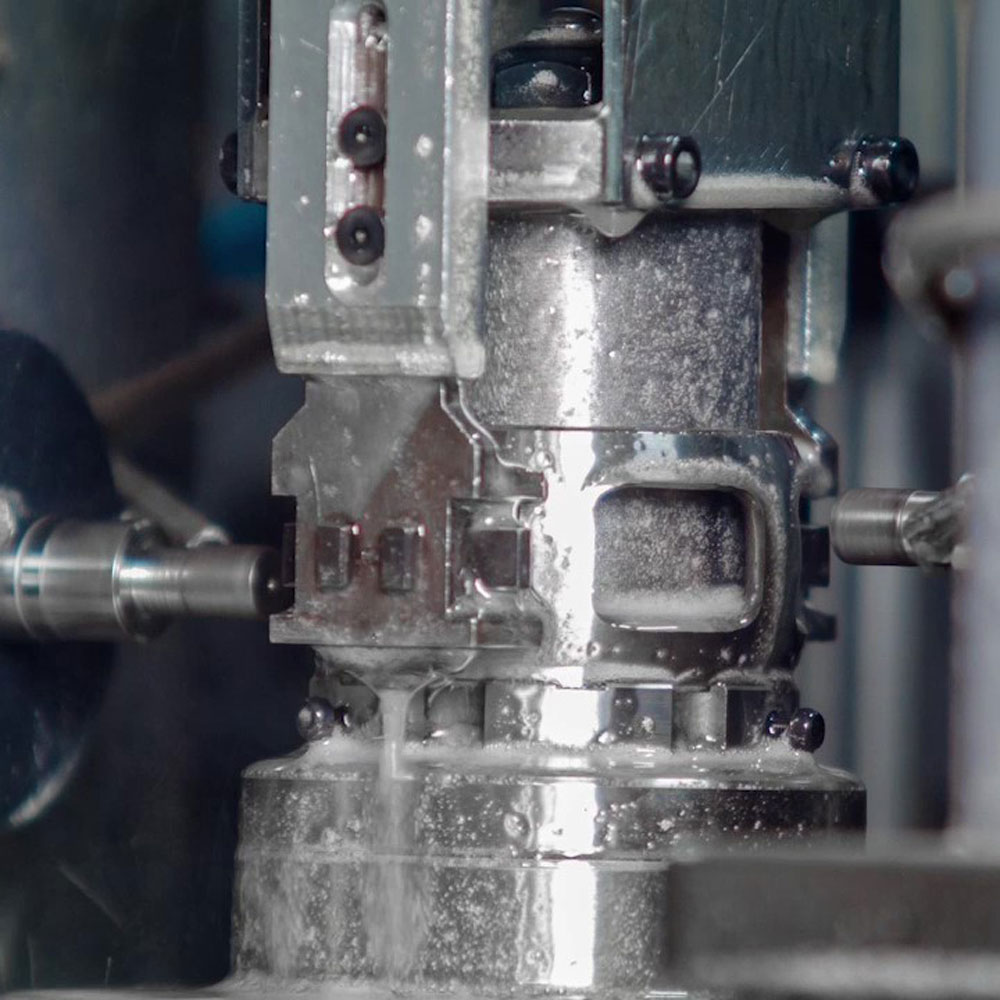

CV Joint Automotive Parts Cage Window Grinding Machine

max bed rotary diameter:Φ40-Φ80mm

max turning diameter:50 mm

max turning length:40 mm

Work part spindle:

spindle head type: Φ80mm

spindle speed:3000 rpm

Product Detail

The machine can complete all grinding operations for the cage windows of CV joints in a single setup. It ensures long-term stability under heavy duty machining through its high-rigidity integral cast bed and rectangular hardened guideways.

The spindle vertical adjustment mechanism allows precise regulation of the grinding amount and height errors on the window surfaces. The servo-driven workpiece spindle enables high-frequency reciprocating rotation and precise circular indexing, while the dedicated pneumatic fixture ensures reliable clamping and consistent accuracy.

Product Advantages

Complete Processing in a Single Setup

The optimized process layout and dedicated fixture design allow all window surfaces of the cage to be fully ground in one clamping, eliminating repositioning errors.

High Rigidity and Durable Structure

The combination of an integral cast bed and high rigidity rectangular hardened guideways provides strong vibration resistance, maintaining machine accuracy and stability under prolonged heavy loads.

Intelligent Precision Compensation System

Equipped with a spindle vertical adjustment mechanism for fine tuning grinding amounts and height errors on window surfaces. Paired with the high frequency rotation and precise indexing of the servo driven workpiece spindle, it ensures consistent machining quality.

Dedicated Pneumatic Fixture System

Customized pneumatic fixtures deliver reliable clamping force and stable positioning accuracy, meeting the demands of rapid workpiece loading and high precision in batch production.

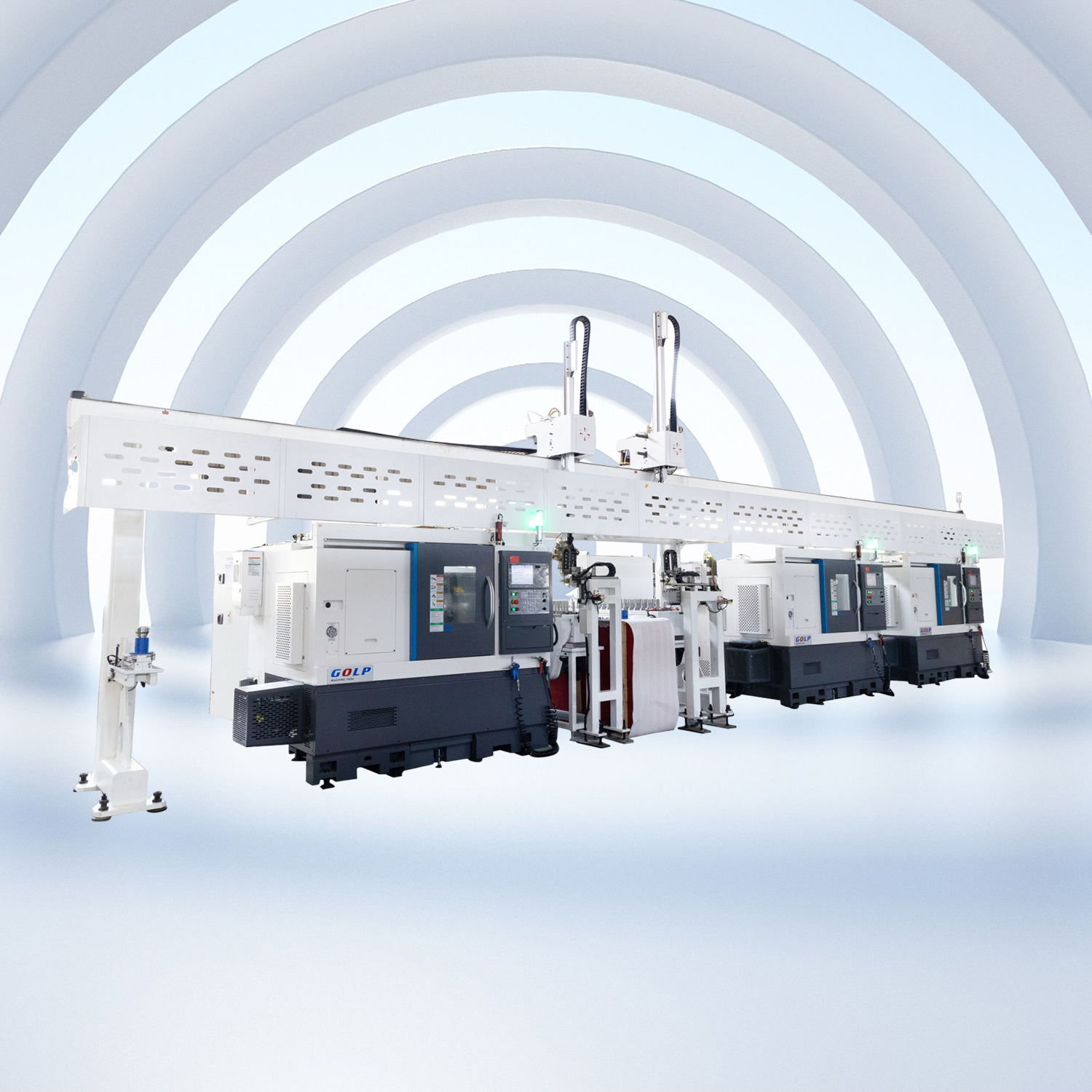

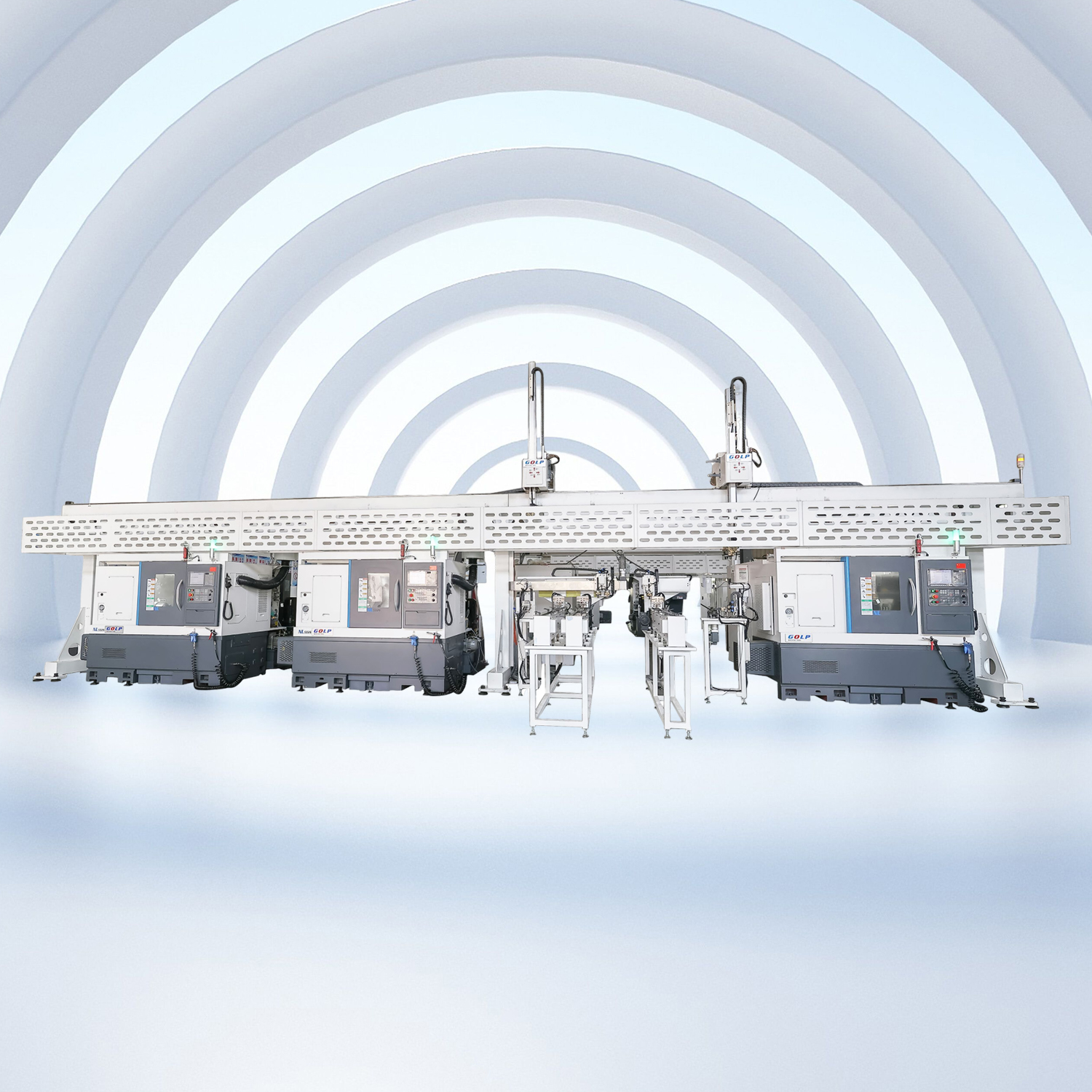

Automation Ready Design

With open interfaces for quick connectivity to gantry robots, the machine can be flexibly integrated into automated production lines.

Workpiece

| CV joint components, such as the outer race, inner race, and cage window, place high demands on machine tools. To enable efficient production, we offer tailored manufacturing solutions. |

Technical Data

Item | Size | Notice | |

processing scope | max bed rotary diameter | Φ40-Φ80mm | |

max turning diameter

| 50 mm | ||

max turning length

| 40 mm | ||

Work part spindle | spindle head type | Φ80mm | |

spindle speed | 3000 rpm | ||

spindle Servo motor power | 1.7 kw | ||

Grinding spindle | Wheel interface specification | M8*1-ø12 | |

Power motor | 4.0kw | ||

max speed | 60000rpm | ||

tool size | Φ10 mm /Φ12mm | ||

Feeding(left-and-right) |

Z1 axis / Z2 axis servo motor | 5.0 NM | |

Z1 axis / Z2 axis travel | 150 mm | ||

Z1 axis / Z2 axis rapid speed | 15 m/min | ||

Up and down size adjustment parts | Type of adjustment | Manual | |

X1 axis / X2 axis travel | 50 mm | ||

clamping unit | max diameter | Φ70mm | |

the travel of tail stock | 50 mm | ||

the type of clamping | Pneumatic Three-jaw | ||

others | Magnetic separator | 0.22 kw | |

cooling water pump | 1.1KW(50L/min) | ||

Power supply

| 380 Volt +/- 10% -50 Hz | ||

total capacitance | 13 KVA | ||

Net/Gross weight | 3000/3500KG | ||

size(L*W*H) | 3705*2500*2074 mm | Refer to the layout for details | |

Recommended Machines

Contact Us for a Quotation

We are pleased to offer you further details and a comprehensive quotation. Feel free to contact us using the following options:

Email: info@golpmachinery.com

Thank you for your interest and support!

FAQ

Q: What are the Payment Terms?

A: We accept T/T payment method. A 40% deposit is required to confirm the order, and the remaining 60% must be paid before the shipment is arranged.

Q: What are your trade terms?

A: We offer flexible trade terms including FOB, CFR, and CIF, so you can choose the one that best suits your needs.

Q: When is the delivery time?

A: The estimated delivery time is 3 to 6 months, depending on the order details and production schedule.

Q: What is your minimum order quantity and warranty?

A: The minimum order quantity is one set. We offer a reliable one-year warranty on all machines.

Q: How are the machines packaged?

A: Each machine is carefully packed in a durable wooden crate to ensure safe and damage-free delivery.

Q: How can I choose the most suitable machine?

A: Simply provide us with your technical requirements, and we will suggest the most suitable model. Alternatively, you can choose the model yourself or send us your product drawings, and we will help you determine the best machine configuration.