Ball Cage CNC Turning Lathe Machine For Tripod Housing

Max bed rotary diameter: Ф400 mm

Max turning diameter: Ф300 mm

Max turning length: 500 mm

Roughness:Ra1.6

Spindle Max speed:3000 rpm

Product Details

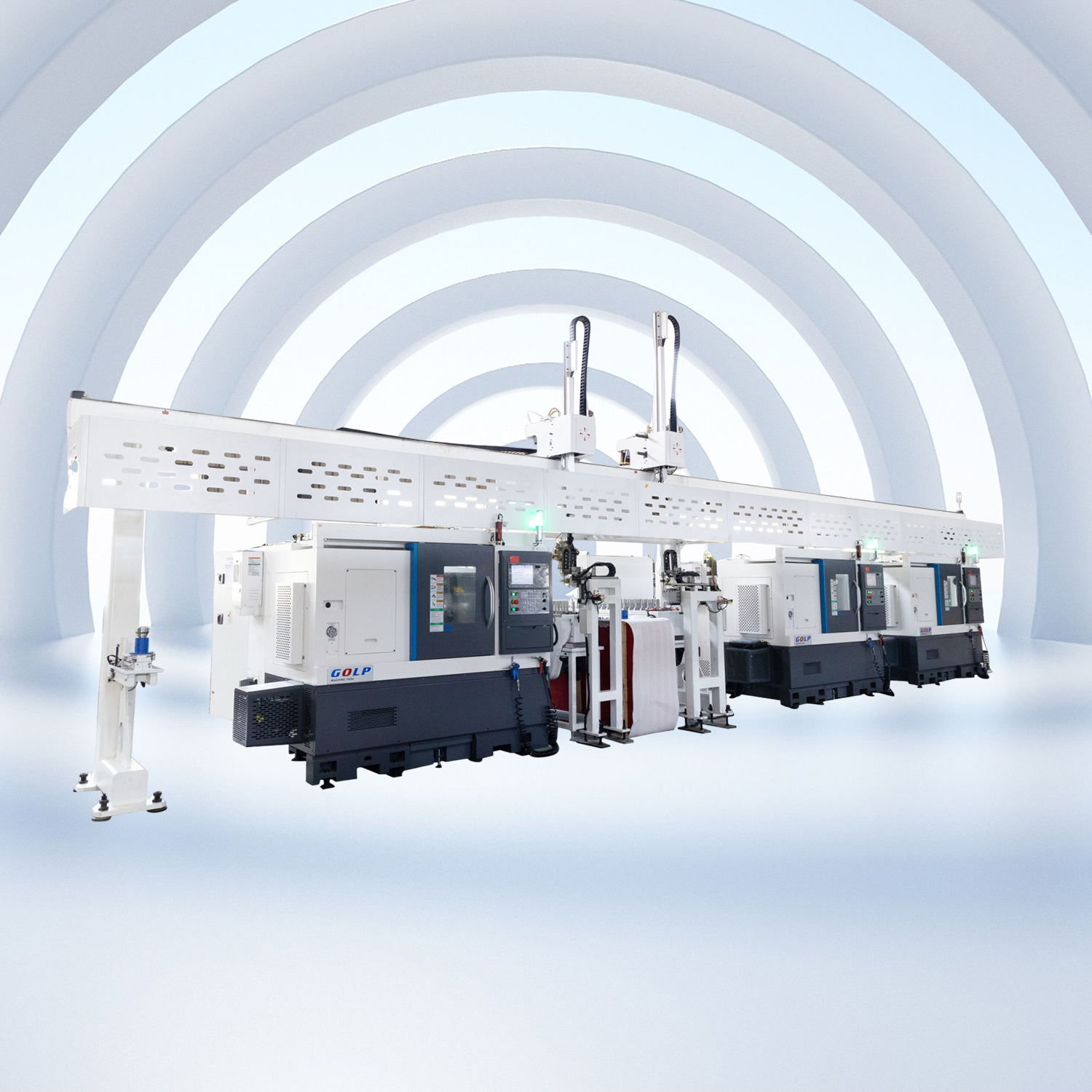

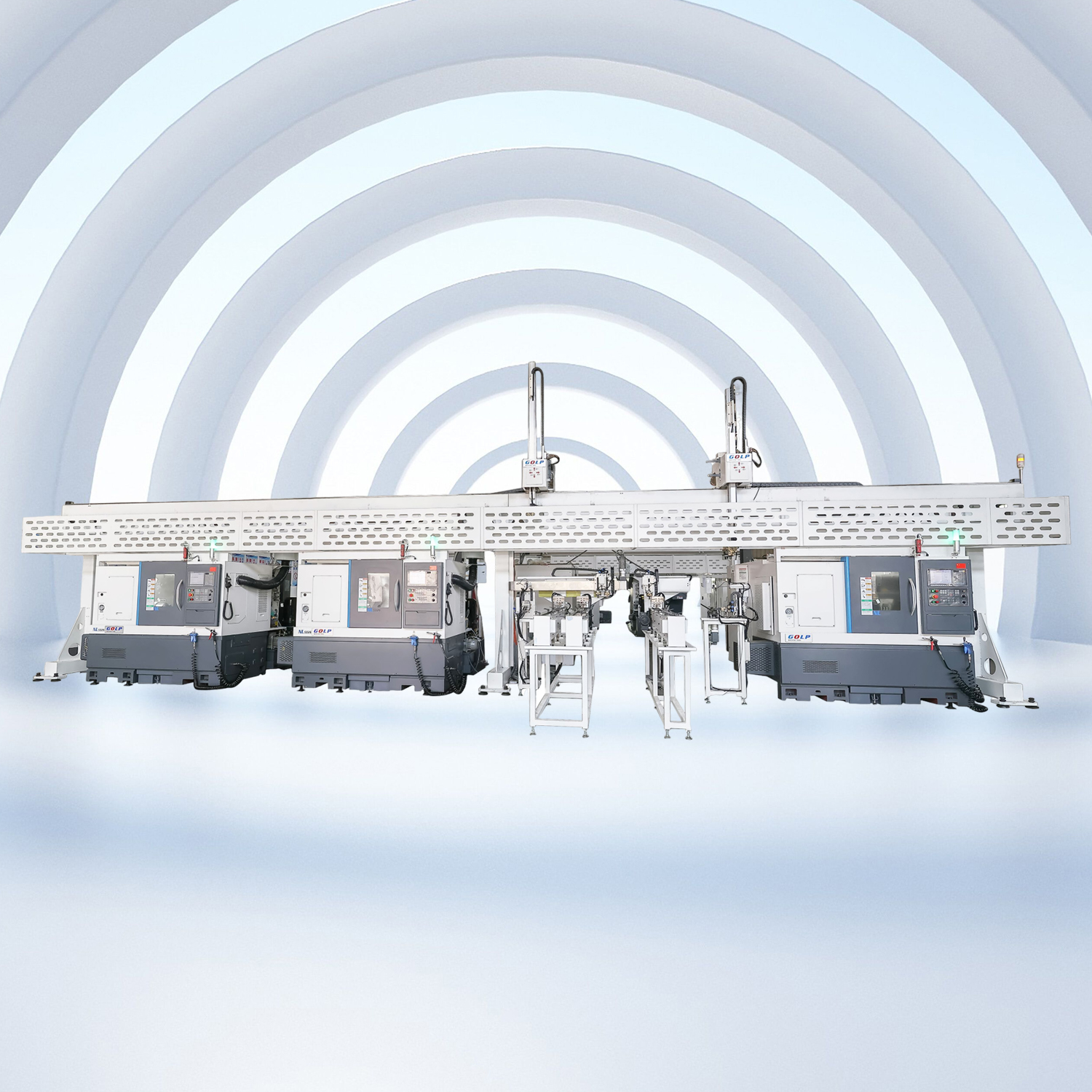

This automated cnc turning lathe machine is designed for precision turning of the bottom section of tripod housings, combining high efficiency, accuracy, and advanced automation. Equipped with a loading magazine, external flipping mechanism, automatic material exchange, and an automated manipulator, it minimizes manual handling while ensuring stable and repeatable part positioning. The 8-station rotary turret with quick-change tooling, hydraulic clamping fixtures, and pneumatic inspection station allows high-precision turning of workpieces up to Ф300 mm in diameter and 500 mm in length, achieving surface roughness up to Ra1.6. The integration of automated handling and inspection ensures consistent quality and productivity.

Product Advantages

Loading magazine and external flipping mechanism for continuous and flexible operation.

Automatic material exchange and gantry robot for unmanned, efficient production.

8-station rotary turret with quick-change tooling for versatile machining.

Hydraulic clamping fixtures ensure secure and precise part holding.

Pneumatic inspection station for real-time quality verification.

High machining performance: max turning diameter Ф300 mm, max length 500 mm, spindle bore Ф55 mm, spindle max speed 3000 rpm, surface roughness Ra1.6.

Specialized turning of tripod housings, delivering accurate and repeatable results

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Workpiece

| CV joint components, such as the outer race, inner race, and cage window, place high demands on machine tools. To enable efficient production, we offer tailored manufacturing solutions. |

Technical Data

No. | Item | Size | |

1 | Processing scope | Max. bed rotary diameter | φ 400mm |

Max. turning diameter | φ 300mm | ||

Max. turning length | 500mm | ||

2 | Spindle | Spindle head type | A2-6 |

Spindle bore tap | MT 6 | ||

Spindle bore diameter | φ 55mm | ||

Spindle max. speed | 3000rpm | ||

Spindle motor power | 11kw | ||

X-axis/Z-axis servo motor | 1.8/1.8kw | ||

3 | Feeding | X/Z-axis travel | 195/500mm |

X/Z-axis rapid speed | 18/24m/min | ||

4 | Servo turrets | Turn and lock it | 0.3s |

Tool number | 8 | ||

Tool size | CAPTO C4 | ||

5 | Other | Auto chip removing | 0.2kw |

Cooling water pump | 5.5kw | ||

Pump station | 1.5kw | ||

Total capacitance | 18KVA | ||

Voltage ;Voltage frequency | 380V, three phrase; 50HZ | ||

G/N weight | 2800/3500kg | ||

Size (L*W*H) | 2200*2800*1750 | ||

6 | Color | According to customer standard | |

Recommended Machines

Contact Us for a Quotation

We are pleased to offer you further details and a comprehensive quotation. Feel free to contact us using the following options:

Email: info@golpmachinery.com

Thank you for your interest and support!

FAQ

Q: What are the Payment Terms?

A: We accept T/T payment method. A 40% deposit is required to confirm the order, and the remaining 60% must be paid before the shipment is arranged.

Q: What are your trade terms?

A: We offer flexible trade terms including FOB, CFR, and CIF, so you can choose the one that best suits your needs.

Q: When is the delivery time?

A: The estimated delivery time is 3 to 6 months, depending on the order details and production schedule.

Q: What is your minimum order quantity and warranty?

A: The minimum order quantity is one set. We offer a reliable one-year warranty on all machines.

Q: How are the machines packaged?

A: Each machine is carefully packed in a durable wooden crate to ensure safe and damage-free delivery.

Q: How can I choose the most suitable machine?

A: Simply provide us with your technical requirements, and we will suggest the most suitable model. Alternatively, you can choose the model yourself or send us your product drawings, and we will help you determine the best machine configuration.

.jpg)

.jpg)