CNC Automated Gear Machining Production Line and Feeding Manipulator Solution

In modern automotive parts manufacturing, CNC automation has become a key technology for improving production efficiency and ensuring machining accuracy. Especially in the processing of gears, shaft components, and constant velocity (CV) joints, an automated production line enables continuous, high precision machining while significantly reducing labor costs and increasing output.

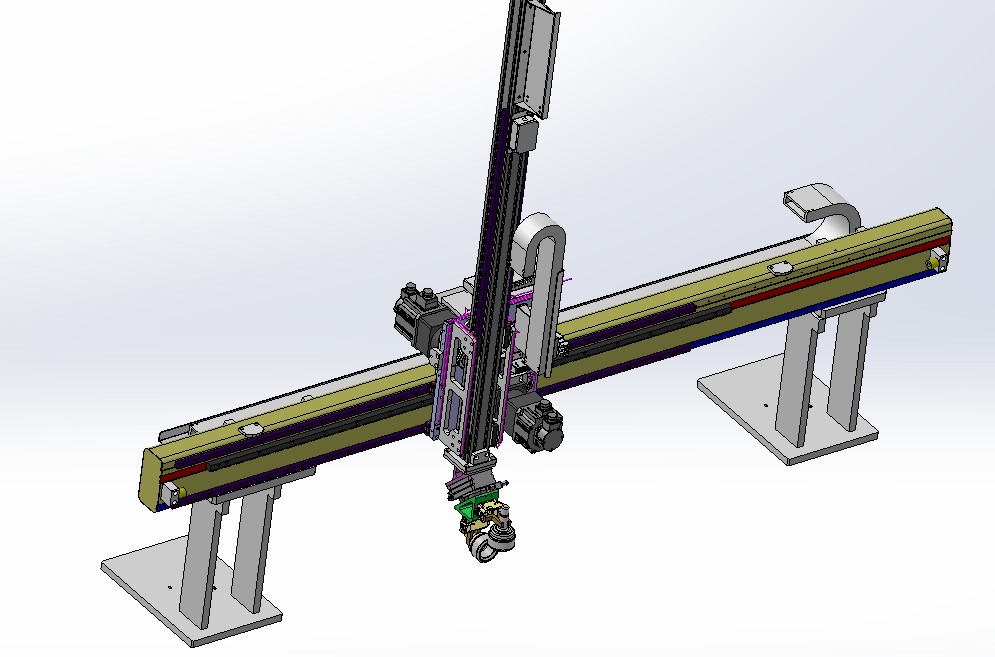

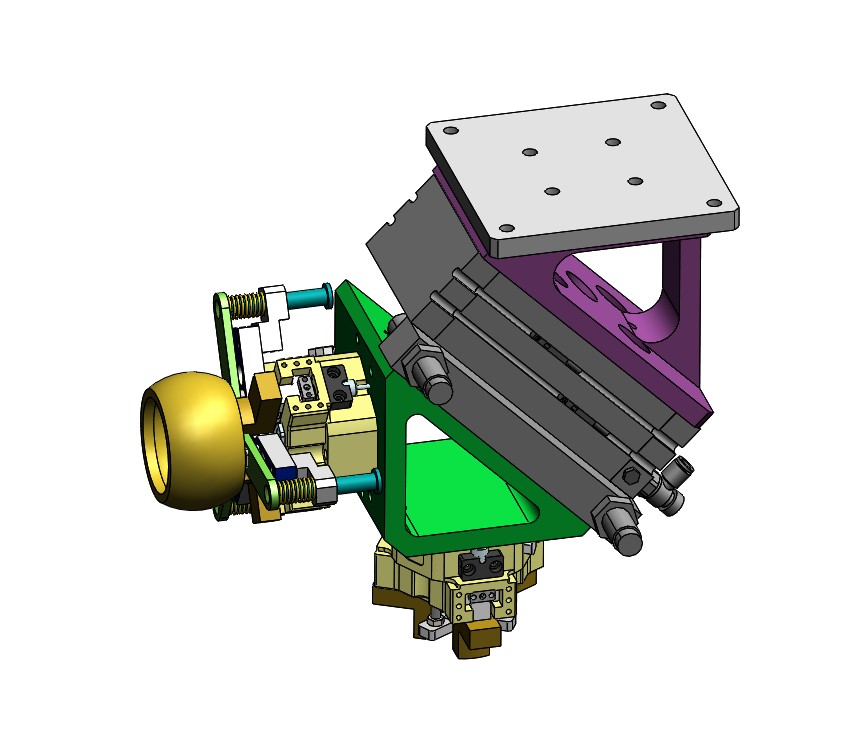

Throughout the entire machining process, the Feeding Manipulator plays a core role. As an essential part of CNC automation systems, it works in coordination with CNC machines, automatic loading and unloading systems, and inspection devices to achieve efficient grinding, chamfering, and rolling of gear and shaft components. By integrating an automatic feeding system with a CNC machine loading manipulator, manufacturers can build a complete automated production line, ensuring precise positioning and stable machining of every workpiece to meet the high consistency and reliability requirements of the automotive industry.

Role of the Feeding Manipulator in CNC Automation

In traditional machining processes, workpiece loading and unloading mainly rely on manual operation, which increases labor intensity and often leads to unstable cycle times, positioning errors, and safety risks. With feeding manipulators supplied by a professional feeding manipulator supplier, raw workpieces can be automatically loaded onto CNC machines and unloaded after machining, forming a closed loop automation process.

The high precision positioning capability of the manipulator ensures repeatable accuracy during key processes such as grinding, chamfering, and rolling, while significantly reducing errors caused by manual handling.

In addition, feeding manipulators can be integrated with other automation modules such as conveyor systems, vision inspection systems, and gantry robots, enabling unmanned production from raw material to finished parts. This greatly improves productivity and ensures stable operation, especially for mass production and continuous night-shift manufacturing.

Construction and Advantages of Automated Production Lines

By combining a single CNC machine with a feeding manipulator, automatic inspection equipment, and conveyor systems, a complete automated production line can be established. Such a production line offers several advantages:

Improved production efficiency:

Automated loading and unloading significantly reduce idle time, allowing CNC machines to operate continuously.

Stable machining accuracy:

Precise positioning between processes ensures consistency of gears and shaft components.

Reduced labor costs:

Minimal operator intervention enables unmanned or lights-out production.

Flexible scalability:

The number of manipulators or machining stations can be adjusted according to production volume requirements.

With these advantages, manufacturers can achieve higher output, more stable quality, and optimized factory operating costs.

Typical Applications

CNC automated production lines are widely used in the manufacturing of automotive gears and drivetrain components.

Typical applications include:

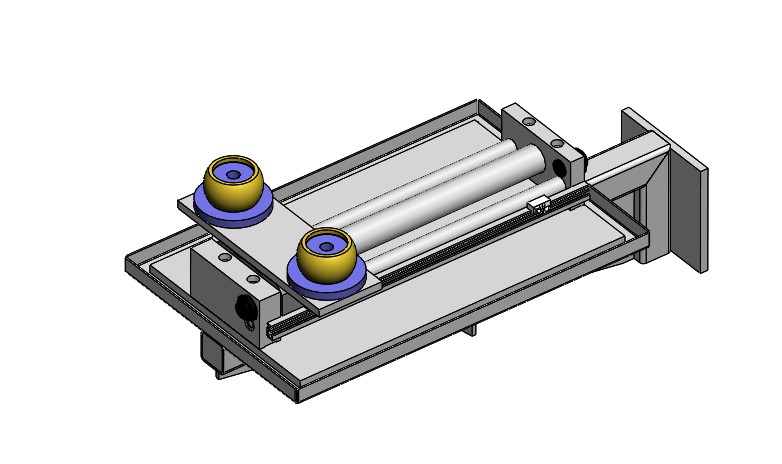

The combination of gear hobbing or grinding machines with feeding manipulators to achieve automatic loading and unloading of gear blanks, while ensuring gear profile accuracy through automatic inspection systems.

For shaft components, feeding manipulators quickly and accurately load workpieces onto CNC lathes or milling machines, enabling automated chamfering and rolling processes.

These applications not only improve productivity but also ensure machining consistency and stability, enabling manufacturers to meet the strict quality standards of the automotive industry in high volume production.

Choosing the Right Feeding Manipulator Supplier

When building an automated production line, selecting a reliable feeding manipulator supplier is critical. A qualified supplier should be able to:

Provide customized CNC machine loading manipulator solutions;

Seamlessly integrate with existing CNC machines and automation systems;

Adapt to different workpiece types and specialized fixtures;

Offer complete technical support and after sales service to ensure long term stable operation;

By working with the right supplier, manufacturers can quickly establish efficient and reliable automation solutions and achieve full-process automation from raw material to finished product.

Conclusion

The development of CNC automated production lines has become an inevitable trend in modern automotive parts manufacturing. As a core automation module, the Feeding Manipulator significantly improves machining efficiency, ensures machining accuracy, and reduces labor costs. By integrating an automatic feeding system with CNC machines, manufacturers can build a complete automated production line for automotive parts, achieving continuous, stable, and high quality production to support capacity expansion and manufacturing upgrades.